PRECISION

TUBE BENDING

MACHINES

30% Faster Production | ±0.1° Accuracy | 3+ Years Durability

PRECISION ENGINEERED SOLUTIONS

Advanced tube bending machines designed for furniture, automotive, medical equipment, and electric vehicle industries.

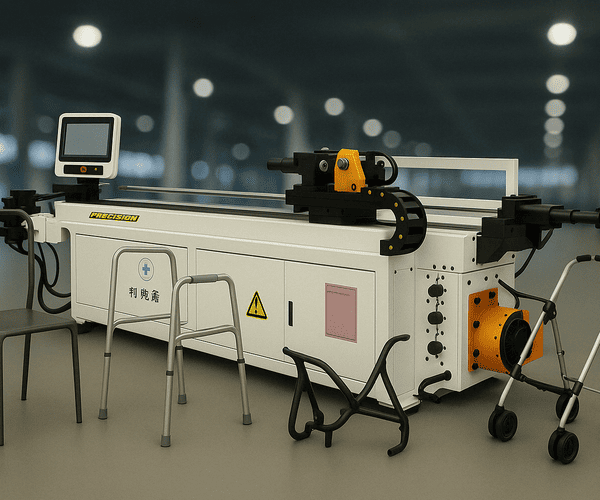

MULTI-AXIS BENDING MACHINE

Advanced servo control with multiple axis coordination for complex tube geometries.

DUAL-HEAD SERVO BENDER

Double productivity with synchronized dual-head operation for high-volume production.

AUTOMATED PRODUCTION LINE

Complete automation solution: bending, cutting, hole punching, and tube shrinking in one line.

COMPLETE SERVICE ECOSYSTEM

From initial consultation to lifetime support, we provide comprehensive services that ensure your success at every stage.

TECHNICAL CONSULTATION

Expert analysis of your production requirements and custom solution design.

INSTALLATION & TRAINING

Professional installation, commissioning, and comprehensive operator training.

LIFETIME MAINTENANCE

24/7 support, preventive maintenance, and genuine spare parts supply.

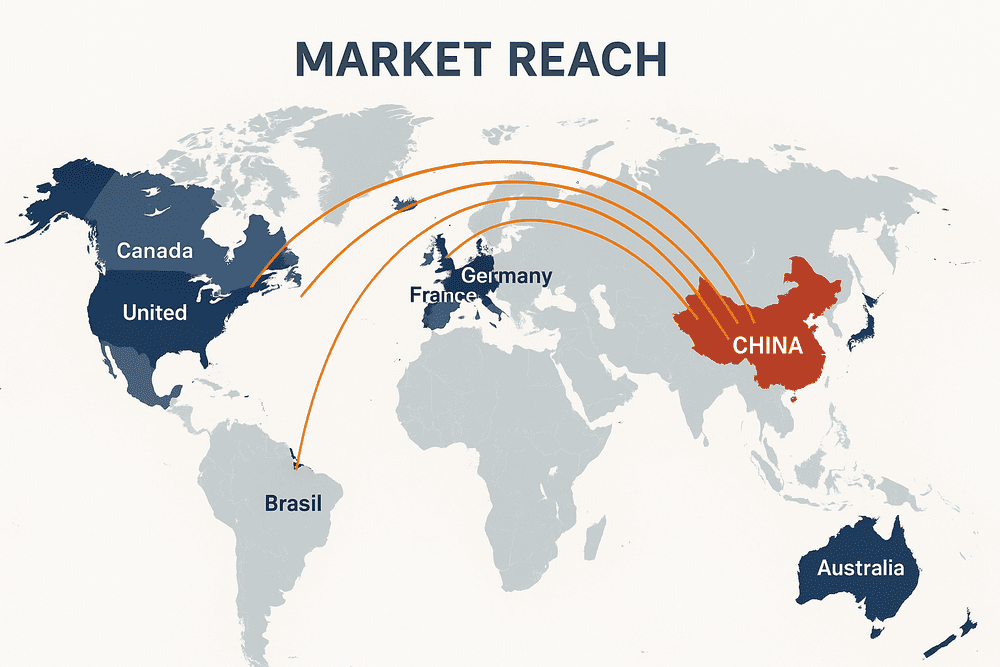

PROVEN RESULTS WORLDWIDE

Trusted by leading manufacturers across furniture, automotive, medical, and e-mobility industries.

US FURNITURE MANUFACTURER

Transformed 20-person manual production into 2-person automated line, achieving 30% productivity increase while eliminating workplace injuries.

LARGE FURNITURE GROUP

Integrated bending, cutting, hole punching, and tube shrinking processes into single automated line, dramatically improving efficiency and quality.

GLOBAL MANUFACTURING PARTNER

Serving manufacturers worldwide with localized support and international quality standards.

SOUTHEAST ASIA

MIDDLE EAST

CENTRAL ASIA

SOUTH AMERICA

GET YOUR FREE PRODUCTION ANALYSIS

Receive a comprehensive evaluation of your current tube bending processes and discover how much you can save with our automation solutions.